What Industries Use CNC Precision Machining?

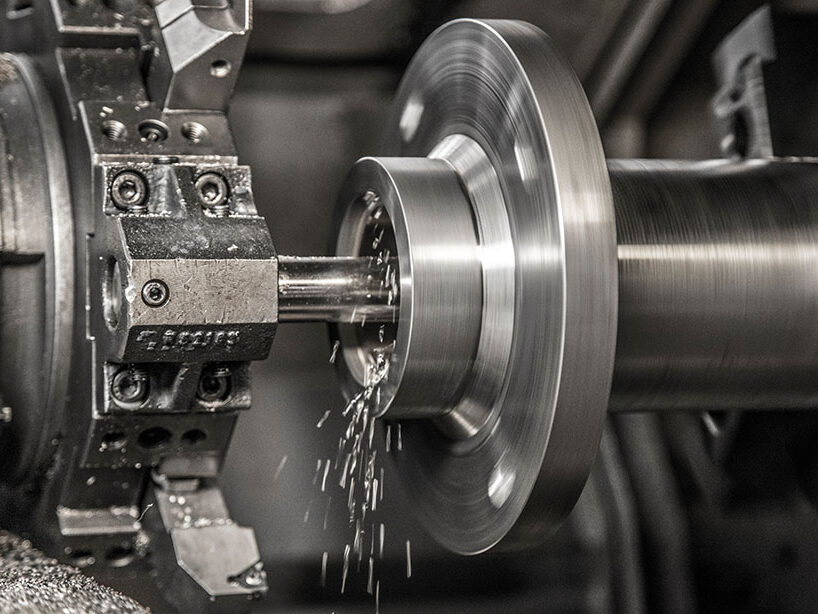

CNC precision machining has become a cornerstone of modern manufacturing, offering unparalleled accuracy, consistency, and efficiency. The ability to produce precision CNC machining parts has allowed numerous industries to innovate and scale their production processes. From aerospace to medical devices, precision CNC machining parts are vital to many sectors that demand high levels of precision and reliability.

At Newtop Industry Group, we specialize in delivering superior precision CNC machining parts that meet the rigorous demands of various industries. Our expertise ensures that no matter your sector, you can trust us to provide high-quality components tailored to your specific requirements.

1. Aerospace Industry

The aerospace industry is one of the most demanding sectors when it comes to manufacturing standards. Aircraft components must adhere to strict regulations and require impeccable precision. Precision CNC machining parts are essential in the production of jet engine components, landing gear parts, turbine blades, and other critical systems that ensure the safe and efficient operation of aircraft.

Aerospace engineers rely on CNC precision machining for its ability to create complex geometries with tight tolerances, ensuring that each part performs flawlessly under high-stress conditions. The use of materials like titanium, aluminum, and high-performance alloys is common in aerospace, all of which can be efficiently machined with CNC technology.

2. Automotive Industry

The automotive industry benefits significantly from precision CNC machining parts, particularly in high-performance and electric vehicles. From engine components to transmission systems, CNC precision machining allows for the mass production of reliable, high-quality parts. Automakers demand parts that provide strength, durability, and precision, and CNC machining offers the versatility to meet these demands.

With the rise of electric vehicles (EVs), CNC machining has become even more critical. Electric motors, battery enclosures, and drivetrain components require precise machining to ensure optimal performance and longevity. Newtop Industry Group plays a key role in this transformation by supplying precision-machined parts for the automotive sector.

3. Medical Device Industry

In the medical device industry, the need for precision is non-negotiable. From surgical instruments to implants, every component must meet strict regulations and standards to ensure patient safety and efficacy. Precision CNC machining parts are used to create components such as bone screws, dental implants, pacemaker housings, and orthopedic devices.

CNC machining offers the medical industry the ability to manufacture parts with intricate designs and high tolerances, often from biocompatible materials like titanium, stainless steel, and medical-grade polymers. Newtop Industry Group provides customized machining solutions to meet the unique needs of the medical device industry, ensuring every part is manufactured to exact specifications.

4. Electronics Industry

The electronics industry demands small, complex parts with extremely tight tolerances, and CNC precision machining is perfect for this purpose. Precision CNC machining parts are critical in producing components such as circuit boards, connectors, housings, and heat sinks. As technology continues to advance, CNC machining is essential in maintaining the precision and miniaturization needed for modern electronics.

With electronics becoming increasingly integrated into daily life, from smartphones to wearable devices, the demand for precision in electronic components continues to grow. CNC machining provides the perfect balance of efficiency and accuracy needed to produce these intricate parts at scale.

5. Defense and Military Industry

The defense and military sectors also heavily rely on precision CNC machining parts for the production of equipment and machinery. From firearms to radar systems, precision is key in ensuring that military equipment functions accurately and reliably in the field. CNC machining allows for the production of durable, high-quality components used in vehicles, weapons, and communication systems.

Materials like steel, titanium, and advanced composites are often machined to exact specifications to ensure the performance and safety of military hardware. Newtop Industry Group is experienced in meeting the stringent demands of defense contractors, providing components that meet military-grade specifications.

6. Energy Industry

The energy sector, particularly in renewable energy and oil and gas industries, relies on CNC precision machining for the production of specialized equipment and machinery. Precision CNC machining parts are used in turbines, pumps, valves, and drilling equipment, all of which require high levels of precision and durability to withstand harsh environmental conditions.

In renewable energy, CNC machining is essential in the production of components for wind turbines, solar panels, and hydroelectric systems. These parts must be manufactured to tight tolerances to ensure efficiency and longevity in energy production.

7. Industrial Equipment and Machinery

Manufacturers of industrial equipment and heavy machinery often turn to precision CNC machining parts for producing critical components. From machine tools to industrial pumps, CNC machining provides the precision and durability needed for equipment that operates in high-stress environments.

CNC precision machining allows manufacturers to produce components in a variety of materials, including metals, plastics, and composites, ensuring that the parts meet the required performance standards. Newtop Industry Group offers tailored solutions for the industrial machinery sector, ensuring that each component is built to withstand the rigors of industrial use.

8. Consumer Goods Industry

While it may not be immediately apparent, the consumer goods industry also benefits from precision CNC machining parts. From kitchen appliances to sporting goods, CNC machining is used to create components that require precision, such as gears, brackets, and housings. The ability to produce intricate designs with consistent quality makes CNC machining an attractive option for manufacturers of consumer goods.

With growing consumer demand for high-quality products, manufacturers are increasingly turning to CNC machining to deliver the precision and reliability that today’s customers expect.

Why Choose Newtop Industry Group?

At Newtop Industry Group, we pride ourselves on being a trusted provider of precision CNC machining parts across multiple industries. Our state-of-the-art CNC machinery and highly skilled team allow us to meet the strict requirements of industries ranging from aerospace to consumer goods. Here’s why you should choose us:

• Unparalleled Expertise: Our team of engineers and machinists has extensive experience in providing custom CNC machining solutions for a variety of industries.

• Quality Assurance: We adhere to stringent quality control processes, ensuring that each part we produce meets the highest standards of precision and durability.

• Advanced Technology: Our investment in the latest CNC technology allows us to deliver complex parts with tight tolerances and quick turnaround times.

• Tailored Solutions: We understand that every industry has unique requirements, and we offer customized solutions to meet the specific needs of our clients.

Conclusion

CNC precision machining plays a vital role in a wide range of industries, from aerospace to consumer goods. The ability to produce precision CNC machining parts with high accuracy, reliability, and efficiency has transformed the way manufacturers operate, enabling innovation and growth across sectors. At Newtop Industry Group, we are proud to be at the forefront of this revolution, delivering top-quality CNC-machined parts to clients worldwide.