Choosing high-quality fabricated steel components can make or break the success of any construction, industrial, or manufacturing project. While some businesses attempt to manage metalwork in-house or rely on inexperienced suppliers, many organizations discover that the smartest, most cost-effective, and most reliable approach is to work with a professional steel fabrication company. A trusted fabrication partner brings technical expertise, state-of-the-art equipment, and a commitment to precision that ensures every project is completed to the highest standard.

1. Access to Advanced Expertise and Skilled Professionals

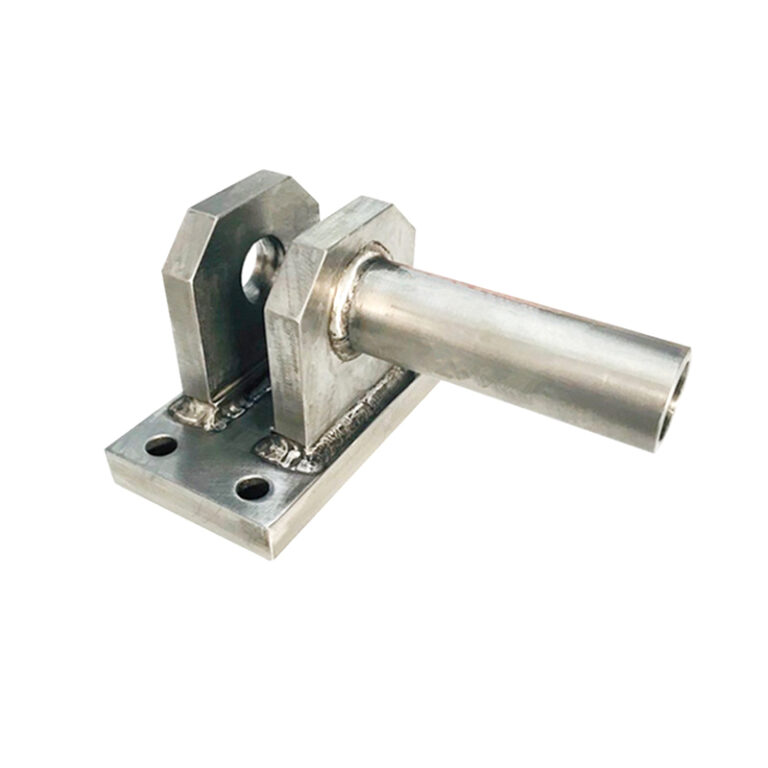

One of the primary reasons businesses partner with a professional steel fabrication company is the depth of knowledge and skill these specialists bring to every project. Fabrication is a highly technical field that requires a deep understanding of metallurgy, cutting techniques, welding processes, structural design, and safety standards. Skilled fabricators are trained to interpret complex drawings, execute precise cuts, and create durable assemblies that meet strict specifications.

A professional fabrication team ensures that even the most intricate or demanding designs are executed flawlessly. Their experience minimizes errors, reduces the risk of structural issues, and guarantees that finished components meet or exceed industry requirements.

2. High-Quality Materials and Reliable Standards

Professional fabricators source steel from reputable suppliers and maintain strict quality control protocols at every stage of production. This ensures that all materials used are structurally sound, corrosion-resistant, and suitable for long-term performance. Companies working with an unqualified provider often face the risk of inconsistent materials or substandard components that compromise safety and durability.

Advanced fabrication shops follow strict regulatory and industrial standards, which helps ensure that every finished product is both compliant and reliable.

3. Modern Equipment and Cutting-Edge Technology

Fabricating steel requires advanced equipment to achieve precise results. Professional fabrication companies invest heavily in modern machinery such as CNC plasma cutters, laser cutters, automated welders, robotic systems, press brakes, and specialized finishing tools. These advanced technologies allow fabricators to deliver extremely accurate cuts, smooth edges, consistent welds, and reliable measurements that are difficult to duplicate without state-of-the-art equipment.

This level of technological investment gives customers the assurance that components will be produced faster, with better accuracy, and with fewer production delays.

4. Customization for Unique Project Requirements

Every project comes with its own set of challenges, from complex architectural designs to specific industrial needs. A professional fabrication partner can tailor their services to meet exact requirements, whether a project calls for custom beams, structural supports, industrial platforms, or decorative metalwork.

The ability to produce tailored components ensures perfect compatibility, seamless installation, and optimal functionality. Professional fabricators analyze project requirements carefully and apply engineering expertise to create solutions that meet both aesthetic and technical goals.

5. Improved Efficiency and Faster Project Timelines

Time is one of the most valuable resources for any construction or industrial project. A professional fabrication company is equipped to handle large volumes of work efficiently thanks to streamlined production processes, experienced staff, and automated systems.

With these capabilities, businesses benefit from:

- Faster turnaround times

- Predictable project schedules

- Reduced downtime

- Smooth coordination with other contractors

Having reliable components delivered on time helps keep the entire project on schedule, minimizing costly delays and ensuring efficient workflow.

6. Enhanced Safety and Reduced Risks

Steel fabrication involves high-risk activities such as cutting, welding, bending, and heavy lifting. Professional fabrication facilities adhere to strict safety protocols, provide extensive staff training, and utilize certified equipment to protect workers and ensure safe production environments.

Partnering with a professional reduces risk for the client, because:

- Components are produced in a controlled environment

- Safety inspections occur at every quality checkpoint

- All fabricated pieces meet industry safety regulations

By relying on experts, companies reduce the chance of on-site accidents and structural failures caused by improperly manufactured parts.

7. Long-Term Cost Savings

While it might seem less expensive to use low-cost fabricators or attempt fabrication in-house, the long-term financial impact tells a different story. Professional fabricators help clients save significantly in the long run by delivering components that are:

- Precisely built

- Long-lasting

- Defect-free

- Easy to install

- Less likely to require costly repairs

Projects completed with high-quality steel fabrication experience fewer maintenance issues, minimize waste, and reduce the need for rework. Additionally, the improved efficiency, reduced labor time, and predictable project outcomes all contribute to substantial cost savings.

8. Stronger Structural Integrity and Durability

Steel is widely used in industries such as construction, energy, transportation, and manufacturing because of its exceptional strength and longevity. When steel components are fabricated by professionals, the integrity of the final structure is significantly enhanced.

Expert fabricators ensure:

- Consistent weld penetration

- Proper alignment of joints

- Accurate dimensional tolerances

- High resistance to wear, stress, and environmental conditions

This precision contributes to a safer, stronger, and more dependable final product.

9. Comprehensive Project Support and Collaboration

A professional fabrication partner does more than simply manufacture steel components—they also provide essential support throughout the project lifecycle. From the initial design and planning stages to installation and post-production assistance, fabricators work closely with engineers, architects, and contractors to ensure that all elements come together seamlessly.

This collaborative approach improves communication, reduces misunderstandings, and helps clients achieve the best possible results.

10. Scalability for Large or Complex Projects

Whether a business needs a single custom component or hundreds of fabricated assemblies, a professional fabrication company has the capacity to scale production based on project requirements. Their ability to manage both small-batch orders and large-scale fabrication makes them the ideal partner for long-term industrial and commercial needs.

Conclusion

Partnering with a professional steel fabrication company is one of the smartest decisions a business can make when working on construction, industrial, or manufacturing projects. With advanced expertise, cutting-edge technology, and a commitment to quality, fabrication specialists deliver durable, precise, and reliable steel components that help projects succeed from start to finish. From cost savings to improved safety and faster production timelines, the benefits of choosing a trusted fabrication partner are clear.